| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | HXSIMD |

| Model Number : | IMD-2307 |

| Certification : | ISO9001/ISO14001/ISO16949 |

| Price : | $16.0/pcs |

| Payment Terms : | T/T, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 3000 Pieces per Day |

| Delivery Time : | 12 work days |

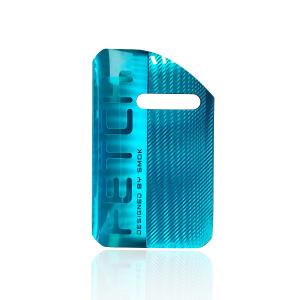

INS Process Decorative Parts Achieve A Certain Degree Of Tactile Sensation And Imitation Wood Effect Through High tension

The INS process, also known as chip injection molding, is a manufacturing process that combines thermal suction molding or high-pressure molding with transfer printing technology. This process can produce workpieces with complex shapes and minimal pattern deformation, achieving a certain degree of tactile and solid wood like effect. However, the shortcomings of the INS process lie in its difficulty in achieving precise positioning, high overall cost, multiple production processes, low efficiency, and low yield.

In addition to the previously mentioned features, the INS process also has the following features:

It can achieve strong texture selectivity and stretchability of irregular structures.

It can only be printed on the surface, and text and patterns are prone to fading.

Difficult to achieve transparent windows or lighting effects.

The achievable patterns are relatively simple.

Overall, the INS process and the IML process each have their own advantages and disadvantages. The former has advantages in texture selectivity and stretchability of irregular structures, while the latter has advantages in printing quality, local transparency, and pattern diversity.

IMD process:

Why choose us

We are the first professional IMD PARTS manufacturer in China,Founded in 2009, the company's industrial park covers an area of more than 30000 square meters, has a high-precision dust-free workshop, and has nearly 100 excellent management personnel, 35 engineering and technical personnel, 50 quality personnel, a total of nearly 500 employees, more than 500 injection molding equipment, and a monthly production capacity of nearly 15 million pieces; From engineering research and development to mold production, diaphragm printing, diaphragm molding, diaphragm injection molding, inspection and packaging, there is a complete process production process.

Full-process dust-free workshop operation

Full-process dust-free workshop operation

Our company has won the honors of high-growth enterprise, industry benchmark enterprise, contract-abiding and creditworthy enterprise, high-tech enterprise, etc

HXS has become a long-term partner of more than ten top 100 enterprises in the world

|